- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

An tSín Cvd sic Monaróirí, Soláthraithe, Monarcha

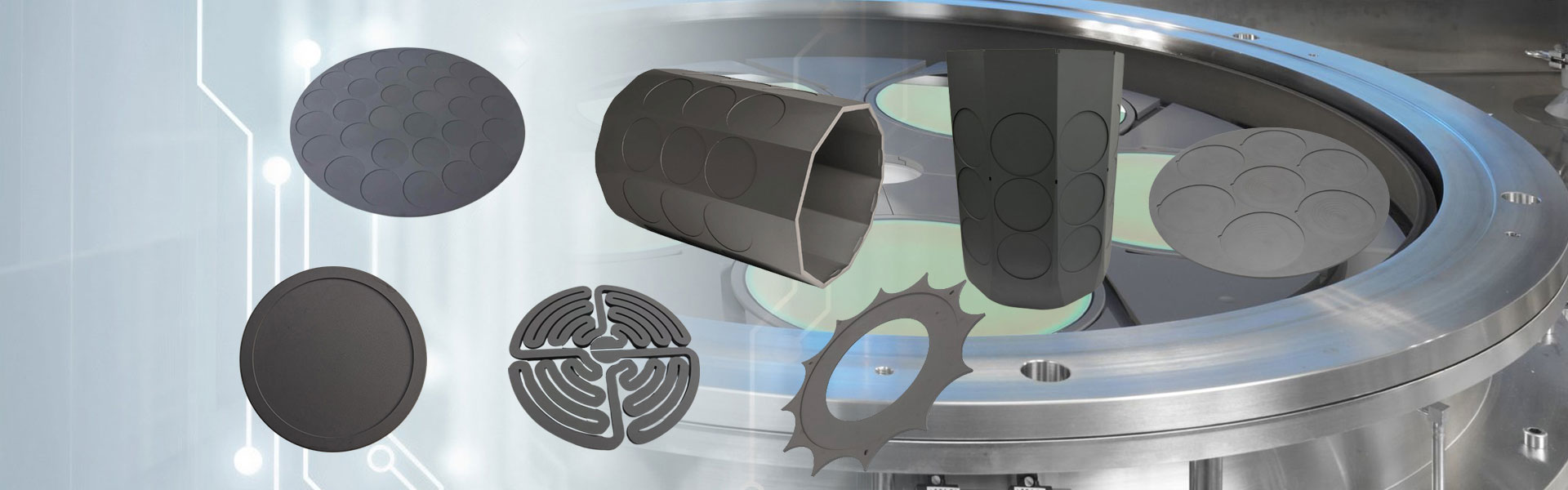

CVD SiC is a vacuum deposition process used to produce high-purity solid materials. This process is often used in semiconductor manufacturing to form thin films on wafer surfaces. During the chemical vapor deposition (CVD) process for producing silicon carbide (SiC), a substrate is exposed to one or more volatile precursors, which chemically react on the substrate surface to form the desired SiC deposit. Among the various methods for producing SiC, CVD produces products with high uniformity and purity, and offers strong process controllability.

Simply put, CVD SiC refers to SiC produced via the chemical vapor deposition (CVD) process. In this process, gaseous precursors, typically containing silicon and carbon, react in a high-temperature reactor to deposit a thin SiC film onto a substrate. CVD SiC is valued for its exceptional properties, including high thermal conductivity, chemical inertness, mechanical strength, and resistance to thermal shock and wear. These properties make chemical vapor deposited (CVD) silicon carbide (SiC) ideal for demanding applications such as semiconductor manufacturing, aerospace components, armor, and high-performance coatings. This material's exceptional durability and stability under extreme conditions ensure its effectiveness in improving the performance and lifespan of advanced technologies and industrial systems.

CVD SiC materials, due to their unique combination of excellent thermal, electrical, and chemical properties, are well-suited for applications in the semiconductor industry, where high-performance materials are required. Chemical vapor deposited (CVD) silicon carbide (SiC) components are widely used in etching equipment, MOCVD equipment, Si and SiC epitaxy equipment, and rapid thermal processing equipment.

The largest market segment for CVD SiC components is etching equipment components. Due to its low reactivity to chlorine- and fluorine-containing etching gases and its electrical conductivity, CVD silicon carbide (SiC) is an ideal material for components such as focus rings in plasma etching equipment. CVD silicon carbide (SiC) components in etching equipment include focus rings, gas showerheads, trays, edge rings.

Take the focus ring, for example. This critical component is placed outside the wafer and in direct contact with it. Voltage is applied to the ring to focus the plasma passing through it, thereby focusing the plasma on the wafer and improving processing uniformity. Traditionally, focus rings are made of silicon or quartz. However, with the advancement of integrated circuit miniaturization, the demand for and importance of etching processes in integrated circuit manufacturing continues to increase. The power and energy of the plasma used for etching are also increasing, especially in capacitively coupled plasma (CCP) etching equipment, which requires even higher plasma energies. Consequently, focus rings made of silicon carbide are becoming increasingly popular.

Due to the high performance of CVD SiC and its ability to be sliced into very thin sections, it can also benefit sputter targets and all types of electrodes.

Process of Chemical Vapor Deposition (CVD)

CVD is a process that transforms a material from a gas phase to a solid phase, used to form a thin film or coating on a substrate surface. The following are the basic steps in CVD:

1. Substrate Preparation

Choose an appropriate substrate material and perform the appropriate cleaning and surface treating to produce a clean, flat surface with good adhesion.

2. Reactive Gas Preparation

Prepare the necessary amount of reactive gas or vapor and inject it into the deposition chamber by some means (gas supply system). The reactive gas can be an organic compound, a metal-organic precursor, inert gas, or other gaseous species.

3. Deposition Reaction

If all instrumentation is setup correctly the CVD process will begin under the pre-defined reaction conditions. The reactive gas that has been injected into the chamber will undergo some chemical or physical reaction on the substrate surface to form a deposit onto the substrate surface. The deposit formation can be the result of several types of processes depending on the deposition method, these include vapor-phase thermal decomposition, chemical reaction, sputtering, epitaxial growth, etc.

4. Control and Monitoring

At the same time during the deposition process, certain deposition parameters need to be controlled and monitored in real time if the observer wishes to ensure the best possible properties in the film are maintained. These include relevant temperature measurement, pressure monitoring, and regulation of gas flow, all the while aiming to keep the desired reaction conditions stable and constant.

5. Deposition Completion and Post-Processing

When either the deposition time, predetermined thickness, or method selected, is achieved the introduction of the reaction gas can be ceased and deposition process ended. Following the deposition, several pertinent post-processing methods (annealing, structural modifications, surface treatment, etc.) should be performed to improve the film performance/quality.

It's important to note that the specific vapor deposition process can vary depending on the deposition technology, material type, and application requirements. However, the basic process outlined above covers most common vapor deposition steps.

- View as

CVD SiC ceann cith

Is comhpháirt lárnach é Ceann Cith Semicorex CVD SiC a úsáidtear i dtrealamh eitseála leathsheoltóra, a fheidhmíonn mar leictreoid agus mar seoladán le haghaidh gáis eitseála. Roghnaigh Semicorex as a rialú ábhar níos fearr, ardteicneolaíocht phróiseála, agus feidhmíocht iontaofa, fhadtéarmach in iarratais leathsheoltóra éilitheacha.*

Leigh Nios moSeol FiosrúchánFáinne Bulc SiC

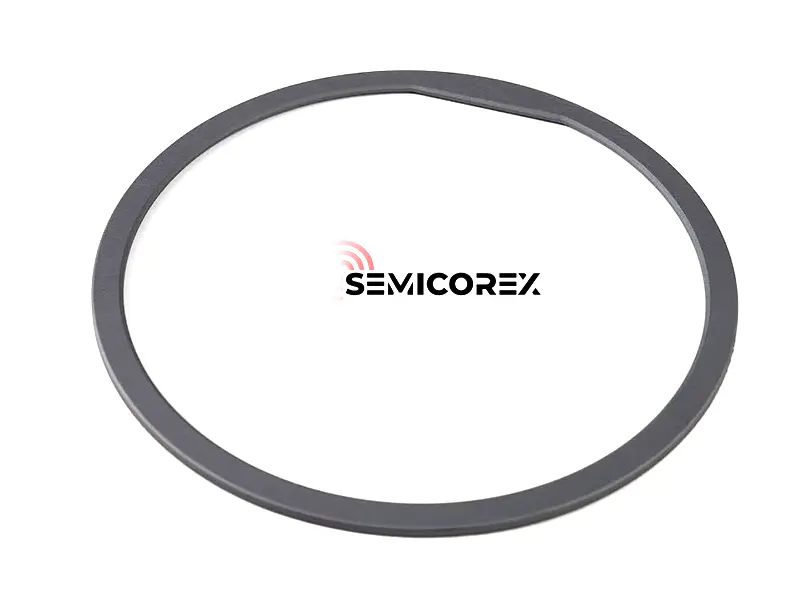

Is comhpháirt ríthábhachtach é Semicorex Bulk SiC Ring i bpróisis eitseála leathsheoltóra, atá deartha go sonrach le húsáid mar fháinne eitseála laistigh de threalamh déantúsaíochta leathsheoltóra chun cinn. Agus ár dtiomantas seasta do tháirgí den scoth a sholáthar ar phraghsanna iomaíocha, táimid réidh le bheith i do chomhpháirtí fadtéarmach sa tSín.*

Leigh Nios moSeol FiosrúchánCeann Cith Silicon Carbide CVD

Is comhpháirt riachtanach agus thar a bheith speisialaithe é Semicorex CVD Silicon Carbide Showerhead sa phróiseas eitseála leathsheoltóra, go háirithe i ndéantúsaíocht ciorcaid chomhtháite. Agus ár dtiomantas gan staonadh maidir le táirgí den scoth a sheachadadh ar phraghsanna iomaíocha, táimid réidh le bheith i do chomhpháirtí fadtéarmach sa tSín.*

Leigh Nios moSeol FiosrúchánCeann cith CVD SiC

Is comhpháirt riachtanach é Semicorex CVD SiC Showerhead i bpróisis CVD nua-aimseartha chun scannáin tanaí aonfhoirmeacha ardcháilíochta a bhaint amach le héifeachtúlacht agus tréchur feabhsaithe. Mar gheall ar rialú sreafa gáis níos fearr CVD SiC Showerhead, a chuireann le cáilíocht an scannáin, agus an saolré fada tá sé fíor-riachtanach le haghaidh feidhmeanna déantúsaíochta leathsheoltóra éilitheacha.**

Leigh Nios moSeol FiosrúchánFáinne Dírithe Soladach Silicon Carbide

Is comhpháirt lárnach é Fáinne Fócasaithe Carbide Sileacain Semicorex Soladach i ndéantúsaíocht leathsheoltóra, suite go straitéiseach lasmuigh den wafer chun teagmháil dhíreach a choinneáil. Trí úsáid a bhaint as voltas feidhmeach, díríonn an fáinne seo an plasma a thrasnaíonn sé, agus ar an gcaoi sin feabhas a chur ar aonfhoirmeacht an phróisis ar an sliseog. Tógtha amháin ó Cheimiceach Deposition Gal Sileacan Carbide (CVD SiC), cuimsíonn an fáinne fócais seo na cáilíochtaí eisceachtúla a éilíonn an tionscal leathsheoltóra. Táimid ag Semicorex tiomanta do mhonarú agus do sholáthar Fáinne Fócais Soladach Carbide Sileacain ardfheidhmíochta a chomhcheanglaíonn cáilíocht le cost-éifeachtúlacht.

Leigh Nios moSeol FiosrúchánCeann Cith SiC

Is comhpháirt riachtanach den phróiseas fáis epitaxial é Ceann Cith Semicorex SiC, atá deartha go sonrach chun feabhas a chur ar aonfhoirmeacht agus éifeachtúlacht sil-leagan scannáin tanaí ar sliseoga leathsheoltóra. Tá Semicorex tiomanta do tháirgí ardchaighdeáin a sholáthar ar phraghsanna iomaíocha, táimid ag tnúth le bheith i do chomhpháirtí fadtéarmach sa tSín.

Leigh Nios moSeol Fiosrúchán