- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

An tSín Graifít isostatach Monaróirí, Soláthraithe, Monarcha

- View as

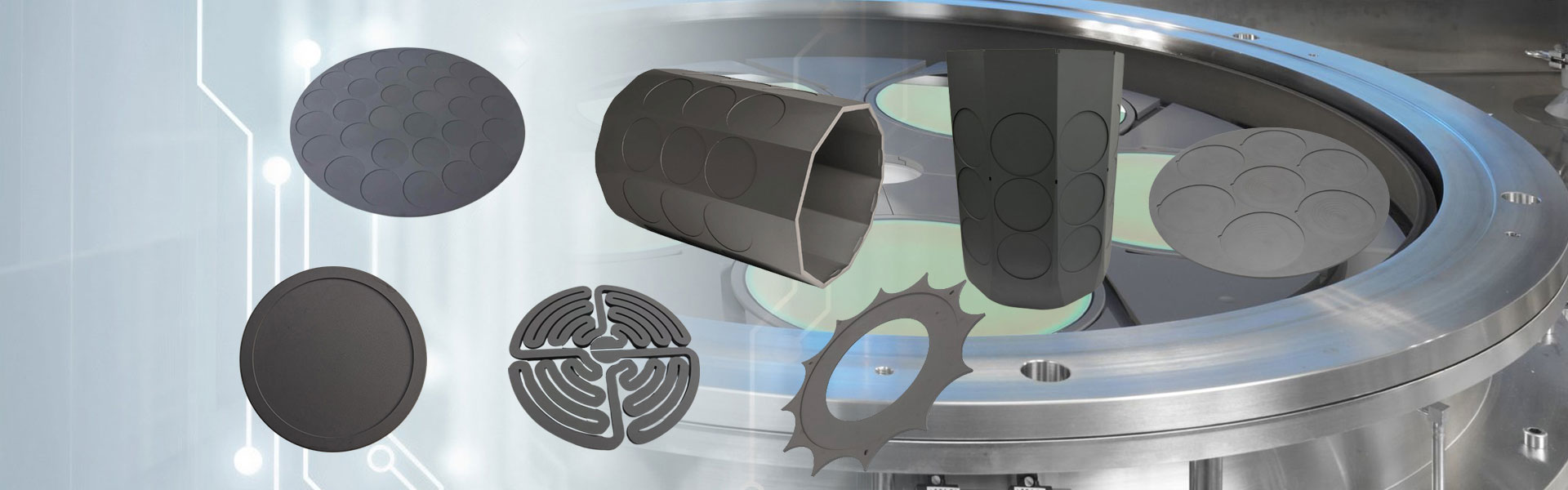

Graifít Chuck

Is comhpháirt ríthábhachtach é Semicorex Graphite Chuck i ndéantúsaíocht polysilicon, a úsáidtear go forleathan sa tionscal gréine. De réir mar a mhéadaíonn an t-éileamh ar sliseoga sileacain ard-íonachta, tá an gá le huirlisí próiseála ardfheidhmíochta ar nós cucks graifít riachtanach. Arna mhonarú ó ghraifít speisialtachta ard-íonachta, tá ár gcucks graifíte deartha chun teochtaí foircneacha, nochtadh ceimiceach, agus strus meicniúil a sheasamh agus cobhsaíocht thoiseach á choinneáil ag an am céanna.

Leigh Nios moSeol FiosrúchánRotar grafite agus seafta

Is codanna ríthábhachtacha iad rótar graifít Semicorex agus tionóil seafta a úsáidtear go príomha le haghaidh dígassing i bruithniú cóimhiotal alúmanaim agus alúmanaim.

Leigh Nios moSeol FiosrúchánSciath Teasa Graphite

Chun éifeachtúlacht próiseála a áirithiú i dtimpeallachtaí crua, déantar Sciath Teasa Semicorex Graphite le hábhair graifíte préimhe agus le teicneolaíocht déantúsaíochta ceannródaíoch.

Leigh Nios moSeol FiosrúchánEilimint Thionsclaíoch Téamh Graphite

Tá eilimint thionsclaíoch téimh graifíte Semicorex ar cheann de na codanna is tábhachtaí d'fhoirnéisí shintéirithe i bhfolús ardteochta. Tá sé riachtanach le haghaidh próisis teirmeacha éagsúla mar gheall ar a gcáilíochtaí ábhartha sofaisticiúla.

Leigh Nios moSeol FiosrúchánBualadh graifít

Tá ról ríthábhachtach ag Semicorex Graphite Bushing, lena saintréithe ábhair uathúla agus inoiriúnaitheacht, i bhfeabhsú feidhmíochta agus fad saoil na gcóras meicniúla, ag cur béime ar a thábhacht i bpróisis innealtóireachta agus déantúsaíochta nua-aimseartha.

Leigh Nios moSeol FiosrúchánFáinne Graifít

Mar gheall ar chumas Semicorex Graphite Ring coinníollacha foircneacha agus éascaíocht an tsuiteála a sheasamh, is comhpháirt fíor-riachtanach iad i dtionscail ar nós hiodrálaic, neomatamaitice agus malartóirí teasa.

Leigh Nios moSeol Fiosrúchán