- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

An tSín Graifít isostatach Monaróirí, Soláthraithe, Monarcha

- View as

Tosú Cré-umha Graifít

Tá tréithe cumas ard-ualaigh ag bushing graifít cré-umha Semicorex, friotaíocht tionchair, friotaíocht ardteochta, cumas láidir féin-bhealaithe, agus féadann sé freisin creimeadh agus sciúradh leachtanna creimneach a sheasamh. Tá an bushing graifít cré-umha seo oiriúnach go háirithe do threalamh atá ag feidhmiú faoi choinníollacha oibre casta ina bhfuil timpeallacht saor ó ola, ard-teocht, ard-ualach, íseal-luas, frith-bréanaithe, frith-chreimeadh, agus frith-radaíochta.

Leigh Nios moSeol FiosrúchánImthacaí Féin-bhealaithe

Is cineál imthacaí iad imthacaí féin-bhealaithe Semicorex a chomhcheanglaíonn airíonna féin-bhealaithe na n-ábhar graifíte. Úsáidtear go forleathan iad i réimsí tionsclaíocha le ceanglais ard lubrication agus coinníollacha comhshaoil casta.

Leigh Nios moSeol FiosrúchánTéitheoir slaite graifít

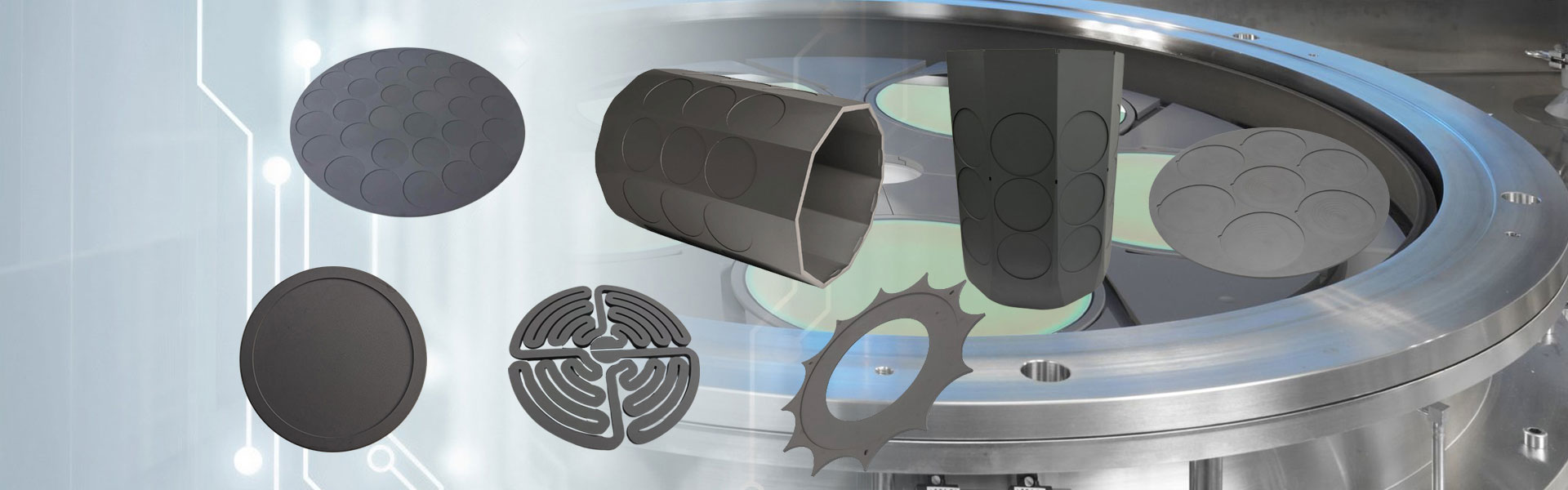

Is eilimint téimh ardfheidhmíochta é Téitheoir Rod Graifít Semicorex atá deartha le haghaidh giniúint aonfhoirmeach ardteochta taobh istigh de fholúis fholús. Roghnaigh Semicorex as a chuid saineolais i dtuaslagáin graifíte beacht-innealtóireachta, ag seachadadh cobhsaíocht theirmeach níos fearr agus feidhmíocht fhadtéarmach atá curtha in oiriúint do do riachtanais thionsclaíocha.

Leigh Nios moSeol FiosrúchánSlat leictreoid graifít

Is comhpháirteanna graifíte ard-íonachta iad slata leictreoidí graifíte semicorex a úsáidtear mar chroí-eilimintí téimh i bhfoirnéisí i bhfolús. Roghnaigh Semicorex le haghaidh cáilíocht ábhair neamh-chomhoiriúnaithe, meaisínithe beachtais, agus feidhmíocht iontaofa i dtimpeallachtaí folúis ardteochta.

Leigh Nios moSeol FiosrúchánPlátaí barr graifíte

Is éard atá i bplátaí barr graifíte Semicorex ná daingneáin bheachtais-innealtóireachta atá deartha chun buidéil ghloine te a láimhseáil agus a láimhseáil i dtimpeallachtaí déantúsaíochta ardteochta. Roghnaigh Semicorex le haghaidh caighdeán ábhair neamh -chomhoiriúnaithe, cumais meaisínithe saincheaptha, agus feidhmíocht chomhsheasmhach a bhfuil muinín ag táirgeoirí gloine ar fud an domhain de.

Leigh Nios moSeol FiosrúchánCrucibles graifíte

Crucibles graifíte semicorex a ndearnadh innealtóireacht orthu le haghaidh cobhsaíocht theirmeach eisceachtúil agus rialú éillithe i bpróisis fáis criostail leathsheoltóra. Roghnaigh ár mbreogáin graifíte le haghaidh íonachta, feidhmíochta agus iontaofachta neamh -chomhoiriúnaithe i bhfás criostail leathsheoltóra. -

Leigh Nios moSeol Fiosrúchán